World of Electronics

Guidelines for circular and sustainable development, production & entrepreneurship

September 27, 2024, 10:00 AM - 12:45 PM

Partly due to the current scarcity of materials and raw materials, circular design is more relevant than ever. Design for circularity contributes to extending the life cycle of products so that they need to be replaced less often. Another important aspect is the reuse and (possible) transformation of raw materials when the product reaches the end of its life.

In product design/production it is important to use sustainable materials/raw materials. How we, as the electronics industry, can contribute to the circular economy is the subject of this seminar.

Program

| Time | Subject | |

|---|---|---|

| 10:00 – 10:25 | A Circular Cleanroom? It exists! Bart-Jan Freriks, director of Interflow | |

| 10:30 – 10:55 | The sustainable design process of the Garage Plug® Jeroen op ten Berg, director/partner of GBO | |

| 11:00 – 11:15 | Break | |

| 11:15 – 11:40 | We are against recycling! “Extend the lifespan of electronics by applying circularity in product development and assembly” Frank Clermonts, Technology director | co-founder AME and Hendri Kortman, Innovation Manager Variass | |

| 11:45 – 12:10 | How to reduce carbon footprint?! Caspar Botter, Chief Commercial Officer at JC-Electronics | |

| 12:15 – 12:40 | “Measuring Together”, trade fair gadget, 'the environmental monitor' in the perspective of Technology, Sustainability and Citizen Participation Andries Lohmeijer, Creative Technical Director at KITT Engineering |

A Circular Cleanroom? It exists!

Sustainability is no longer just about energy and CO2. It is about People and Planet. How can we better align our decisions today with the future? A future in which raw materials can be scarce? Circularity is one of the answers!

Interflow is the first designer, producer and builder of a circular cleanroom or operating room recognized by RVO. Interflow's robust and modular CleanWall® concept, comparable to Lego blocks, plays a crucial role in this. Thanks to this concept, you can get a formal take-back guarantee from the cleanroom builder.

At the end of the period of use, the builder takes back a large part of the components and guarantees a second life for these parts. Together with suppliers, the cleanroom builder can reduce the CO2 footprint of the entire chain to zero. In addition, much more can be achieved with an all-electric cleanroom, emission-free production and electric transport.

We challenge you to think along about the possibilities and wishes. Let's discuss the opportunities that we may still miss together!

Bart-Jan Freriks, director of Interflow

The sustainable design process of the Garage Plug®

The Garage Plug® from our client Total Safety Solutions from Oisterwijk is our groundbreaking innovation for the safety of EV maintenance, immobilizing vehicles during maintenance, ensuring the safety of the user and preventing emergency situations. The plug meets the standards for EV plugs, has an ergonomic and durable design and is equipped with adjustable connectors. Jeroen op ten Berg from GBO gives a presentation about the design process in which sustainable is an important point of attention.

Jeroen op ten Berg, director/partner of GBO

We are against recycling!

“Extend the lifespan of electronics by applying circularity in product development and assembly”

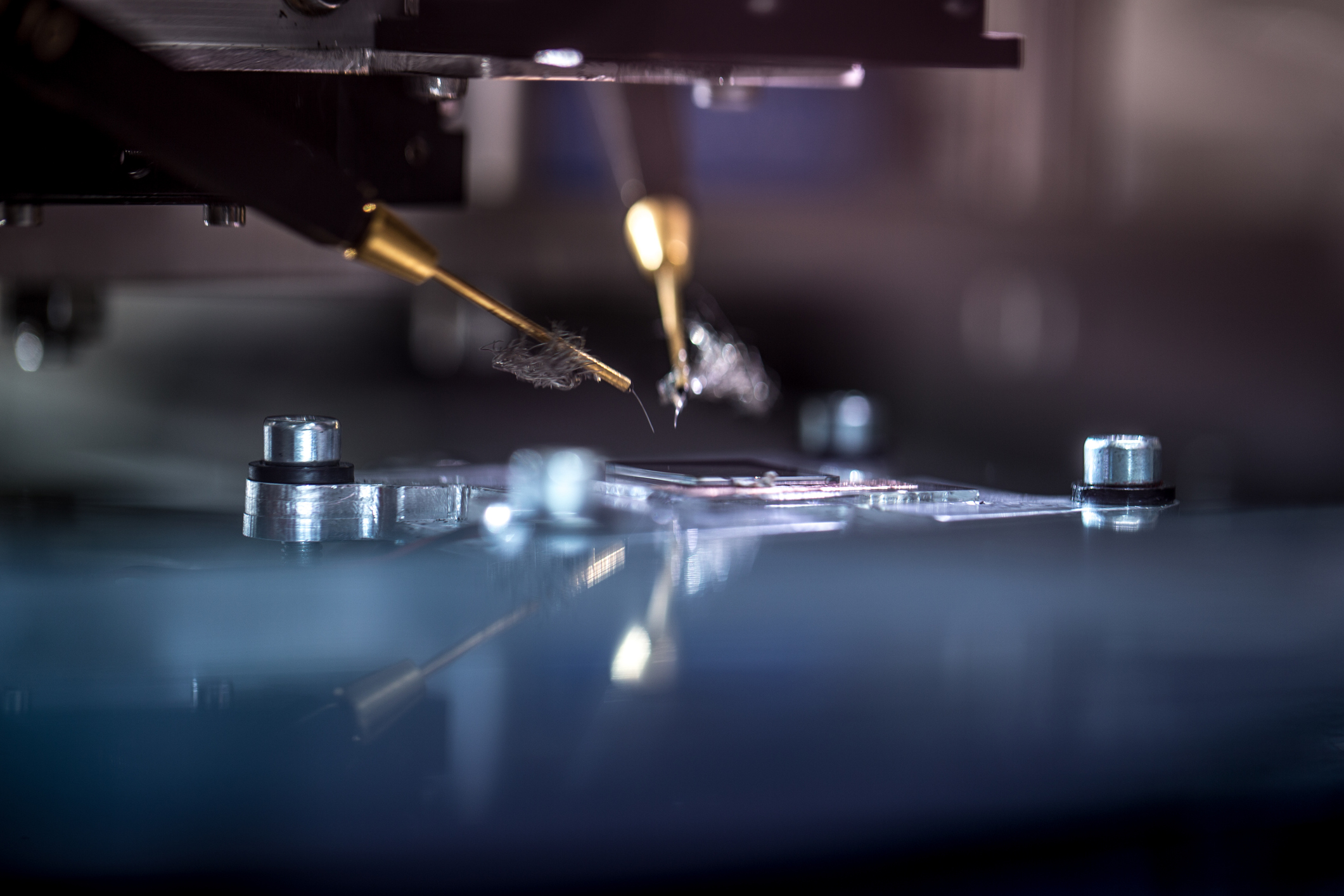

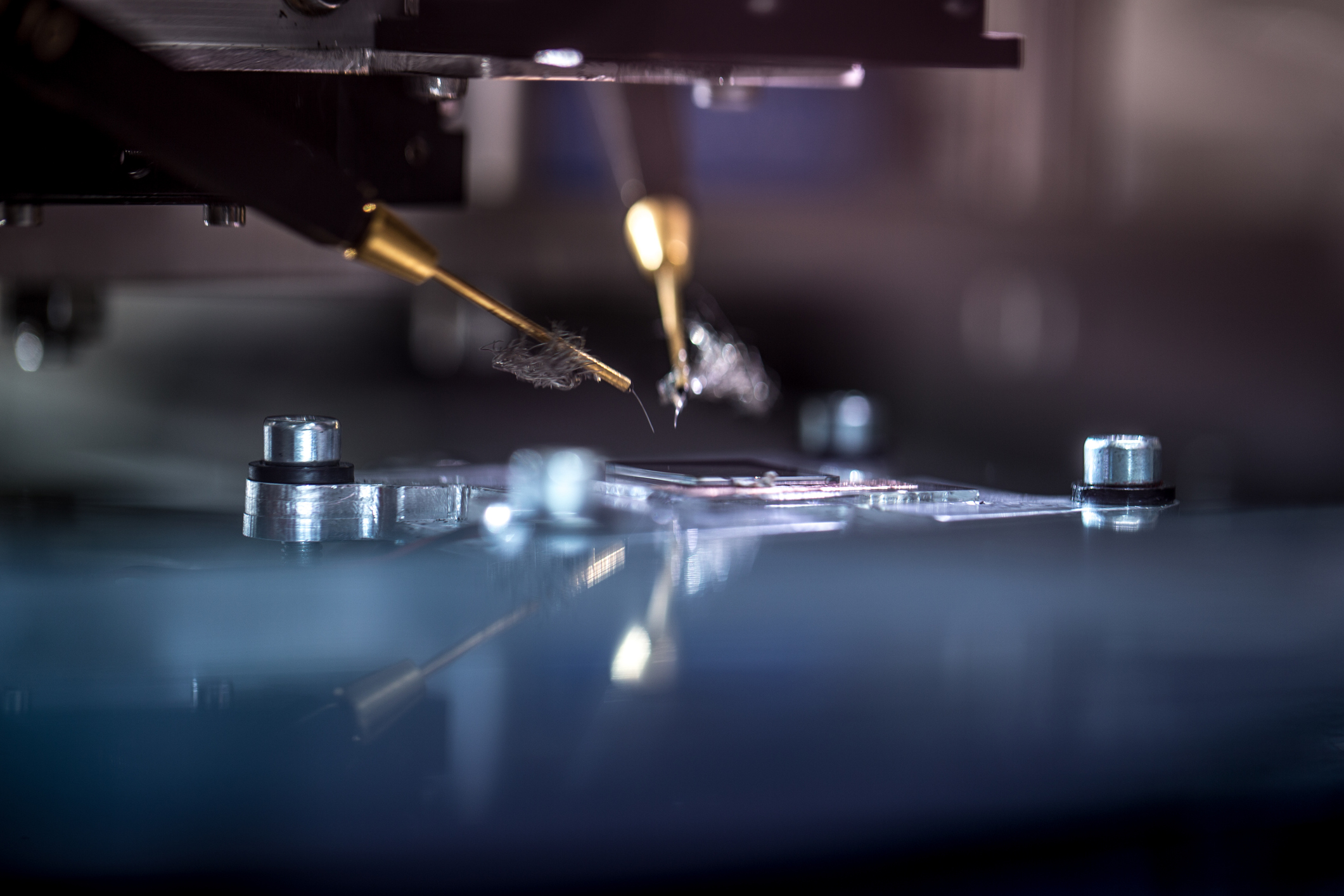

Discover AME and Variass methods to extend the lifespan of electronic products and reduce the environmental impact. AME takes us through the design approach to collect relevant data under different usage conditions. This leads to insight into the lifespan, which enables targeted replacement of components.

Variass will share a case where this refurbishing process is central with the goal of sustainability through reuse. Join this seminar and learn how innovative technologies contribute to a sustainable future for electronics.

Frank Clermonts, Technology director | co-founder AME and Hendri Kortman, Innovation Manager Variass

How to reduce carbon footprint?!

There is a lot of talk about things like CO2 reduction and the circular economy. As JC-Electronics we know that talk is cheap. We have a scientifically proven and validated model that calculates exactly how many raw materials and CO2 can be saved when switching to the use of refurbished industrial electronics.

Besides that, companies have the possibility to use obsolete industrial electronics for a very long time. This also provides environmental benefits because E-waste can be drastically reduced. A number of practical examples of large manufacturers who have already taken this step will be discussed in more detail.

Caspar Botter, Chief Commercial Officer at JC Electronics

“Measuring Together”, trade fair gadget, 'the environmental monitor' in the perspective of Technology, Sustainability and Citizen Participation

It started with the ambition to measure “nitrogen” and thereby contribute to a better insight into the nitrogen deposition in the Netherlands. The required sensitivity for a meaningful NOx measurement turned out to be unachievable. In collaboration with the participating companies and the “Community”, a monitor has now been designed that harvests its own energy, performs various measurements and sends them to an “Open platform”. In a playful way, we show how the “Gadget” ties in with several Sustainable Development Goals of the United Nations.

Andries Lohmeijer, creative technical director at KITT Engineering

Featured companies